As you may already know, M.M.T. Srl is a company that has been designing and manufacturing level regulators and sensors for conductive liquids, as well as insulating materials, granules, and powders since 1974. Our mission is to offer a wide range of products for steam boilers, with well-designed and functional solutions at such competitive prices that they provide the best quality/price ratio.

But today, we’re not here to talk about ourselves; we want to introduce you to the new TDS Series 360! So, if you’re interested in learning more, we invite you to keep reading.

Series 360: Conductivity Transmitter for Measuring TDS in Boilers

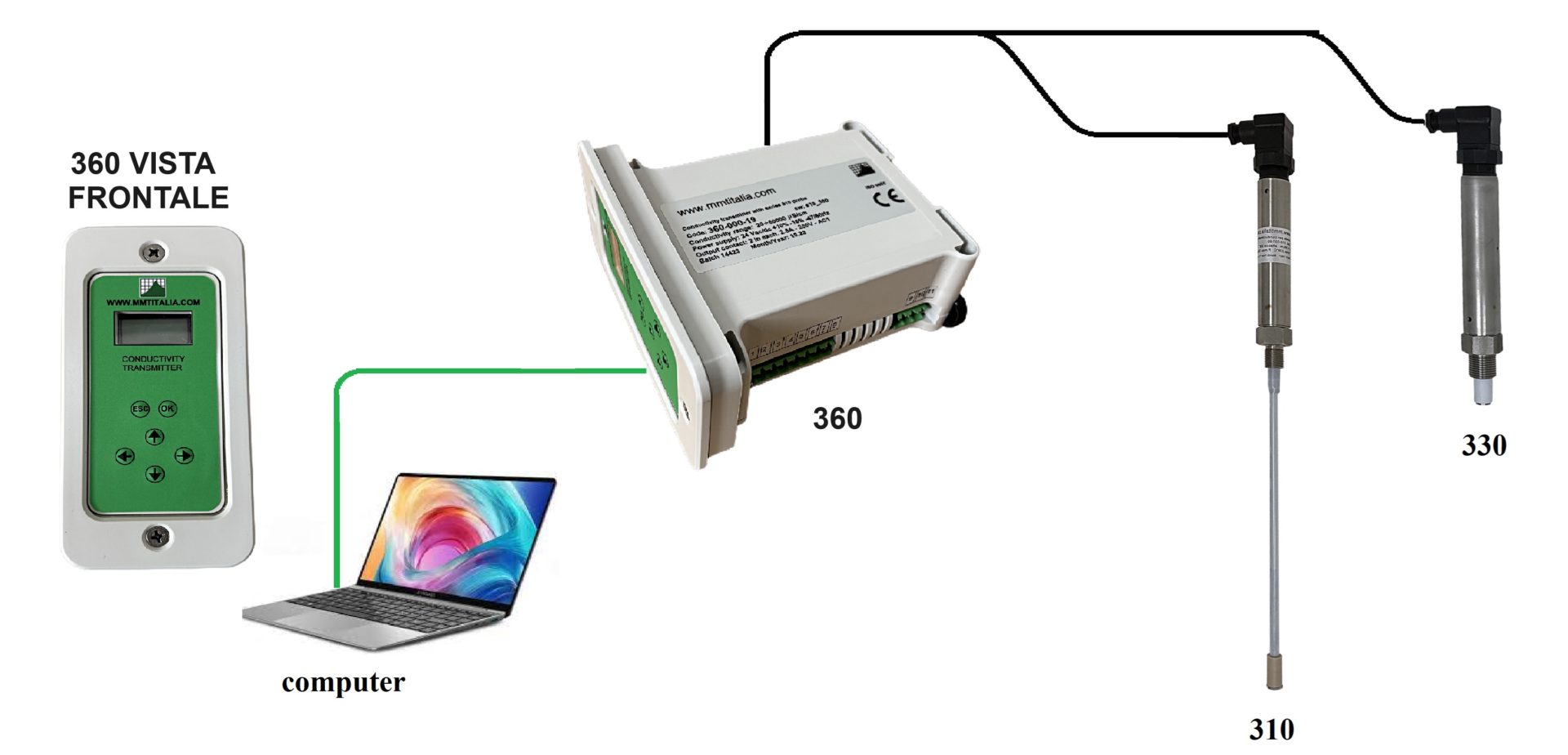

If you’re wondering what it is, you should know that it’s an electronic device designed to be installed inside an electrical panel. Its purpose is to measure the conductivity (also known as TDS) of the water in a boiler when electrically connected to a probe from the 310/330 series, providing a 4–20mA current signal while controlling two threshold relays.

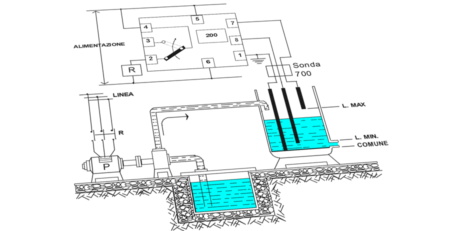

That said, it’s important to understand that continuously monitoring the dissolved salts in boiler water (known in English as Total Dissolved Solids = TDS) is crucial. This ensures the purity of the steam produced (for example, for food or pharmaceutical applications) and helps save on methane consumption for heating the water.

The Series 360 Transmitter, when electrically connected to a Series 310 probe installed in the boiler or a Series 330 probe located along the feed pipe, can measure the water’s conductivity and transmit the value via a standardized current signal (4–20mA). This galvanically isolated current signal can be sent to a PLC, which can use it to control a valve, allowing fresh, pure water to enter if conductivity levels are too high.

If a PLC isn’t available, don’t worry: the 360 transmitter also includes two relays. One is specifically designed for controlling the blowdown valve, while the other triggers an alarm for excessive conductivity levels. As you may know, for conductivity measurements to be accurate, temperature compensation is essential, and this is one of the reasons why our device is so reliable.

Finally, the 360 is equipped with a mini front terminal (6 buttons + an 8×2 character LCD display) for calibration, adjustment, and reading operations. It also features a USB interface for performing the same operations via a tablet or PC.

In this case, the communication software is available on our website.

If you’d like to learn more about our products, click here.