How do capacitive liquid level sensors work?

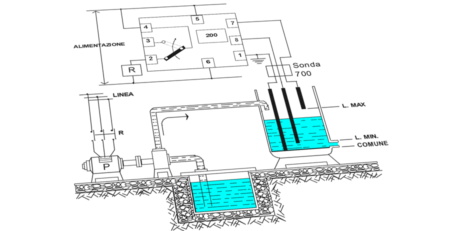

Capacitive sensors detect changes in capacitance caused by the liquid’s presence between two conductive probes. As the liquid level changes, the capacitance varies proportionally, allowing precise and continuous level measurement without direct contact with moving parts.

What types of liquids can capacitive liquid level sensors measure?

They can measure both conductive and non-conductive liquids, including water, oils, chemicals, and food-grade fluids. MMT Italia offers sensors built with materials suitable for aggressive chemicals and hygienic applications.

What are the main advantages of capacitive liquid level sensors?

- High accuracy and continuous measurement capability

- Durability with no moving parts and resistance to harsh environments

- Versatility for different liquids and tank materials

- Easy integration with industrial control systems via analog or digital outputs

What is the difference between point-level and continuous liquid level sensors?

Point-level sensors detect when the liquid reaches a specific height, used for alarms or switches (e.g., high/low level detection).

Continuous level sensors provide real-time, proportional measurement of liquid level throughout the tank.

Which industries benefit most from liquid level sensors?

- Food and beverage (requiring hygienic, FDA-compliant sensors)

- Chemical and pharmaceutical production (needing resistant materials and accuracy)

- Water treatment and wastewater management

- Automotive and hydraulic systems

- HVAC and boiler control systems

How do I choose the right liquid level sensor for my application?

Consider the following:

- Type and conductivity of the liquid

- Measurement type (point-level or continuous)

- Operating environment (temperature, pressure, chemical exposure)

- Compliance standards (hygienic, explosion-proof, FDA)

- Required output and integration options (4–20 mA, Modbus, Profibus)

Are liquid level sensors easy to install and maintain?

Yes. MMT Italia designs sensors for straightforward installation, often with mounting kits and user-friendly configuration. Maintenance usually involves periodic calibration and inspection to ensure accuracy and longevity.

Can capacitive liquid level sensors handle aggressive or viscous fluids?

Absolutely. With specially selected materials like PTFE, stainless steel, and other resistant coatings, MMT Italia’s sensors can withstand harsh chemicals and thick liquids without degradation.

Do you offer customization for liquid level sensors?

Yes. MMT Italia provides tailored sensor solutions designed to fit specific tank sizes, fluid types, and process conditions, ensuring optimal performance and compliance.

What support does MMT Italia provide after purchase?

We offer comprehensive customer support, including technical consulting, installation assistance, calibration services, and ongoing maintenance to maximize your sensor’s reliability and accuracy.